- TikTok Shop

- Tools & Hardware

- Soldering Equipment

- Welding Accessories

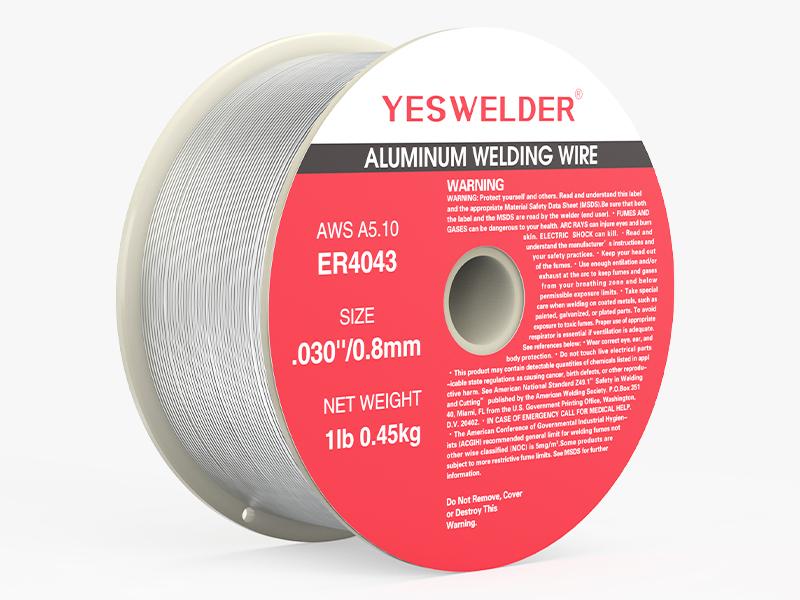

- YESWELDER ER4043 .030"/.035" Diameter 1LB Spool Silicon Aluminum MIG Welding Wire

5

2 global reviews

5

2

4

0

3

0

2

0

1

0

Sort by

Recommended

Filter by

All

Displaying 2 of 2 reviews

Reset filters

D**n

·

Verified purchase

US

It came reasonable time. I haven’t tried it yet but it was sealed in cellophane which is a plus

Item:

.030"2026-01-30

j**2

·

Verified purchase

US

Item:

.035"2025-04-21

About this product

$2?

$5.98 shipping on this order

YESWELDER ER4043 .030"/.035" Diameter 1LB Spool Silicon Aluminum MIG Welding Wire

5(2)

29 sold

Diameter:Please select

.030"

.030" .035"

.035"Quantity:

Buy now

Coupon center

Log in to check your coupons

View and claim any available offers once you're logged in.

Shipping & returns

Shipping & delivery

Many items qualify for free shipping or become eligible once the order threshold is met.

Returns made easy

Most items are eligible for free returns within 30 days of delivery for a refund. Some items, including ingestibles, hygiene products, and pre-owned goods, are non-returnable. Final sale items cannot be returned or replaced.

YesWelder Store

OFFICIAL SHOP

4.6

100.8K Sold

6.9K+ Followers

100%24h response rate

73%Ships within 2 days

89%Positive feedback

Visit

Shop review

Videos for this product

Creator earns commission

Burk’s Garage

575

Creator earns commission

Burk’s Garage

177

Creator earns commission

Burk’s Garage

123

Creator earns commission

Sean

67

Creator earns commission

Burk’s Garage

52

Creator earns commission

Beasley

52

Creator earns commission

Burk’s Garage

35

Creator earns commission

Burk’s Garage

32

Creator earns commission

Burk’s Garage

30

Creator earns commission

Burk’s Garage

26

Creator earns commission

Burk’s Garage

24

Creator earns commission

Burk’s Garage

19

Creator earns commission

Burk’s Garage

16

Creator earns commission

Burk’s Garage

13

Creator earns commission

Burk’s Garage

12

Creator earns commission

Tools.Live

12

Creator earns commission

Tools.Live

11

Creator earns commission

Tools.Live

7

Creator earns commission

Burk’s Garage

3

Creator earns commission

oilybaboon

2

Explore more from YesWelder Store

You may also like

YesWelder Store

5.0

13 sold

$29.99

YesWelder Store

5.0

47 sold

$42.99

YesWelder Store

3.7

70 sold

$23.00

YesWelder Store

4.7

142 sold

$21.99

YesWelder Store

5.0

192 sold

$45.99

YesWelder Store

4.7

2.2K sold

$23.00

People also searched for